-

Corporate

Our Group’s foundation was laid by our late founder, Sh. Sewa Ram Aggarwal, whose vision and guidance has helped the group to command leadership positions across various industries. His vision to become a household name across product categories resonates with the reputation of products in SMC Group’s umbrella.

-

Products

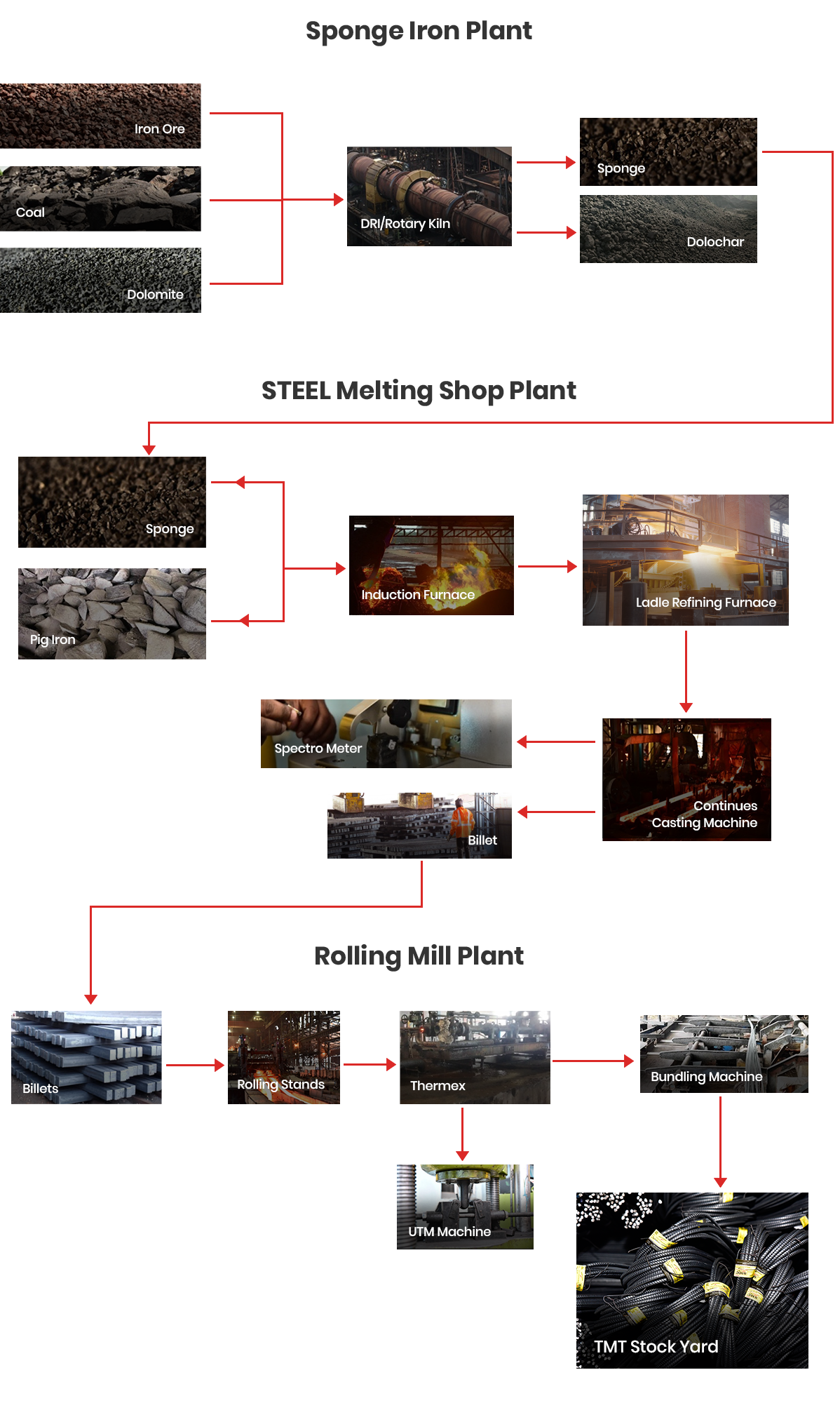

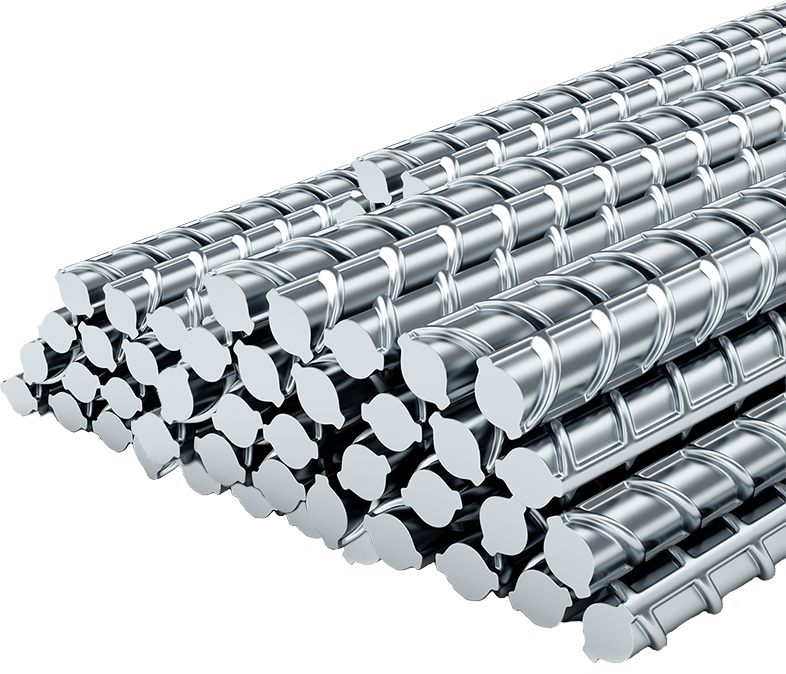

SMC Power Generation Ltd produces Sponge Iron, Billets, TMT Bars and Power in its state-of-the-art integrated plant.

-

Manufacturing Excellence

SMC Power Generation Ltd is the leading producer and supplier of its category products amongst many other leading brands in India, the credit goes to our commitment to excellence in manufacturing processes and stringent quality control at every step of the production and distribution channel.

-

Sustainability

We at SMC Power Generation Ltd have remained ahead to fulfill our social responsibility. All our operations and processes follow people and environment safe practices to reduce the impact on the society at large. We have actively contributed our services towards the support in the community school, drinking water, development of village common areas such as temples, meeting places.

-

Connect with Us

Connect with us to know more about news and articles, our CSR projects, our dealers and distributors at varius locations in India and employment opportunities with our organisation.